Quality Control and Compliance

At Tin Ping Metal Parts, we do not just care about our products we care about the environment we live in, it is our goal to build long-term and health relationships with our clients. For over 30 years, we never stop improving, through constant innovation and rigorous training we are proud to have been certified in various quality and environmental management systems, as well as hazardous substance process management systems.

Tin Ping Metal Parts Limited is the metal parts supplier you can depend on.

Tin Ping Metal Parts Limited is the metal parts supplier you can depend on.

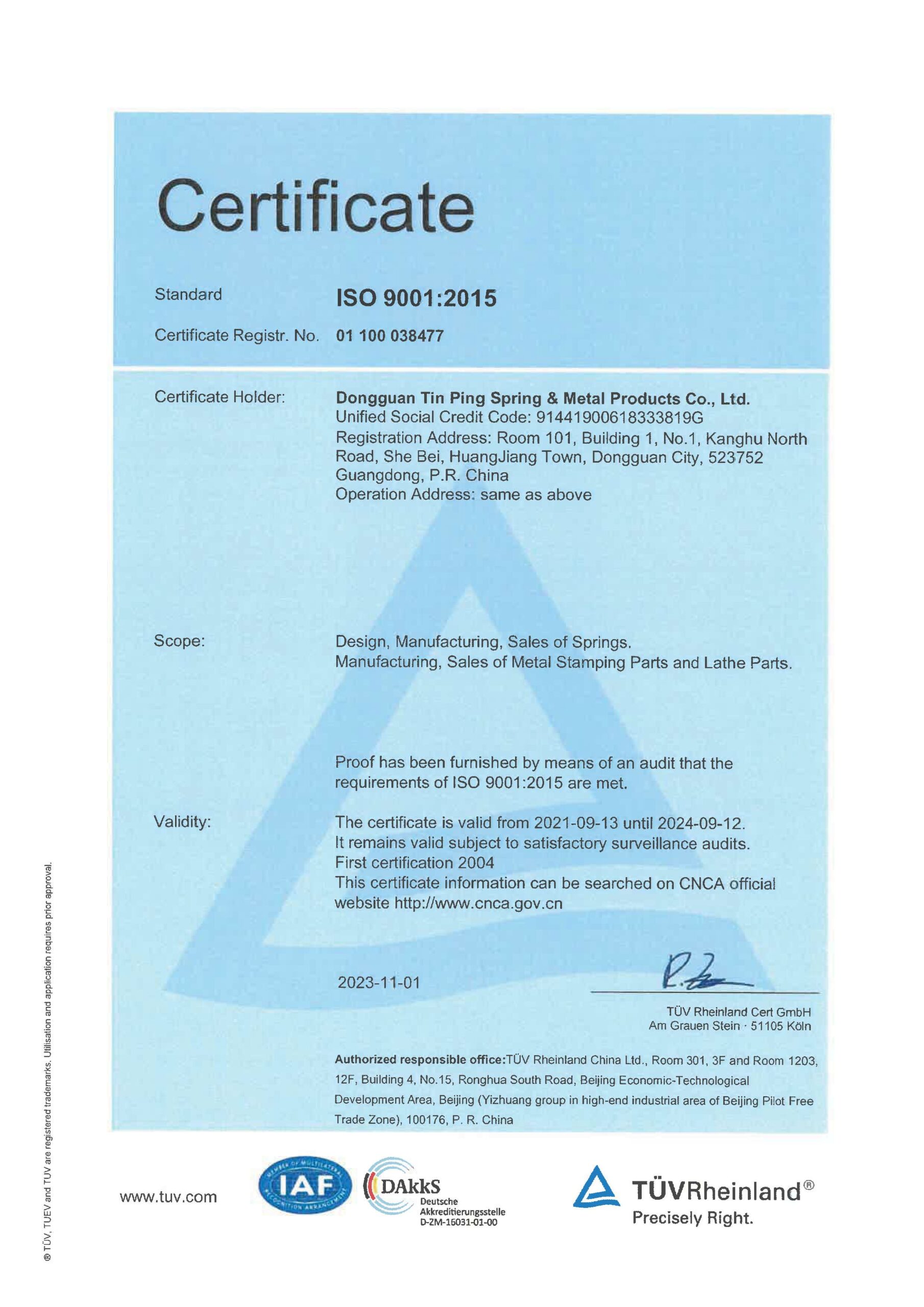

QMS |

ISO9001:2015、IATF16949:2016 |

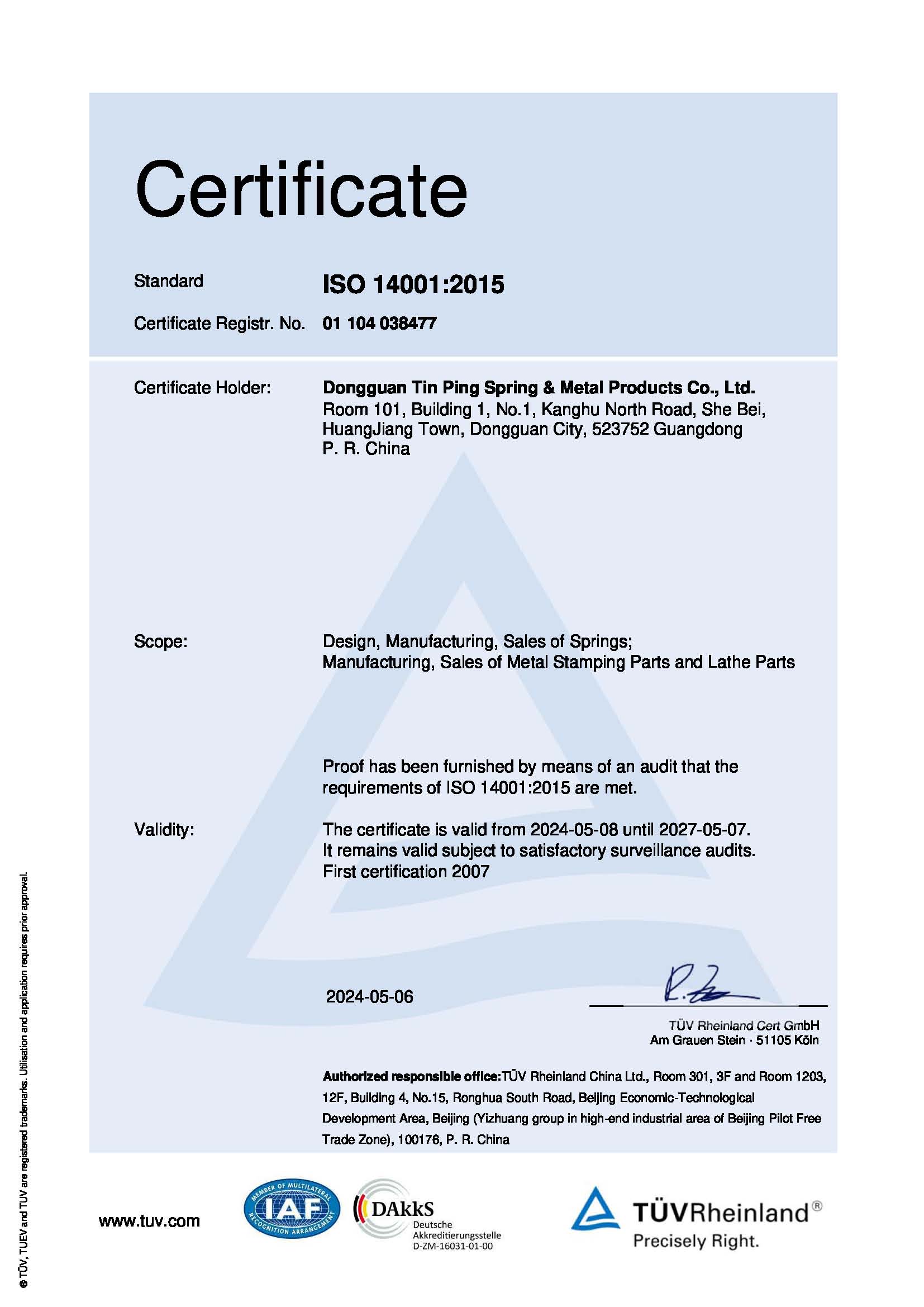

| EMS | ISO140001:2015 |

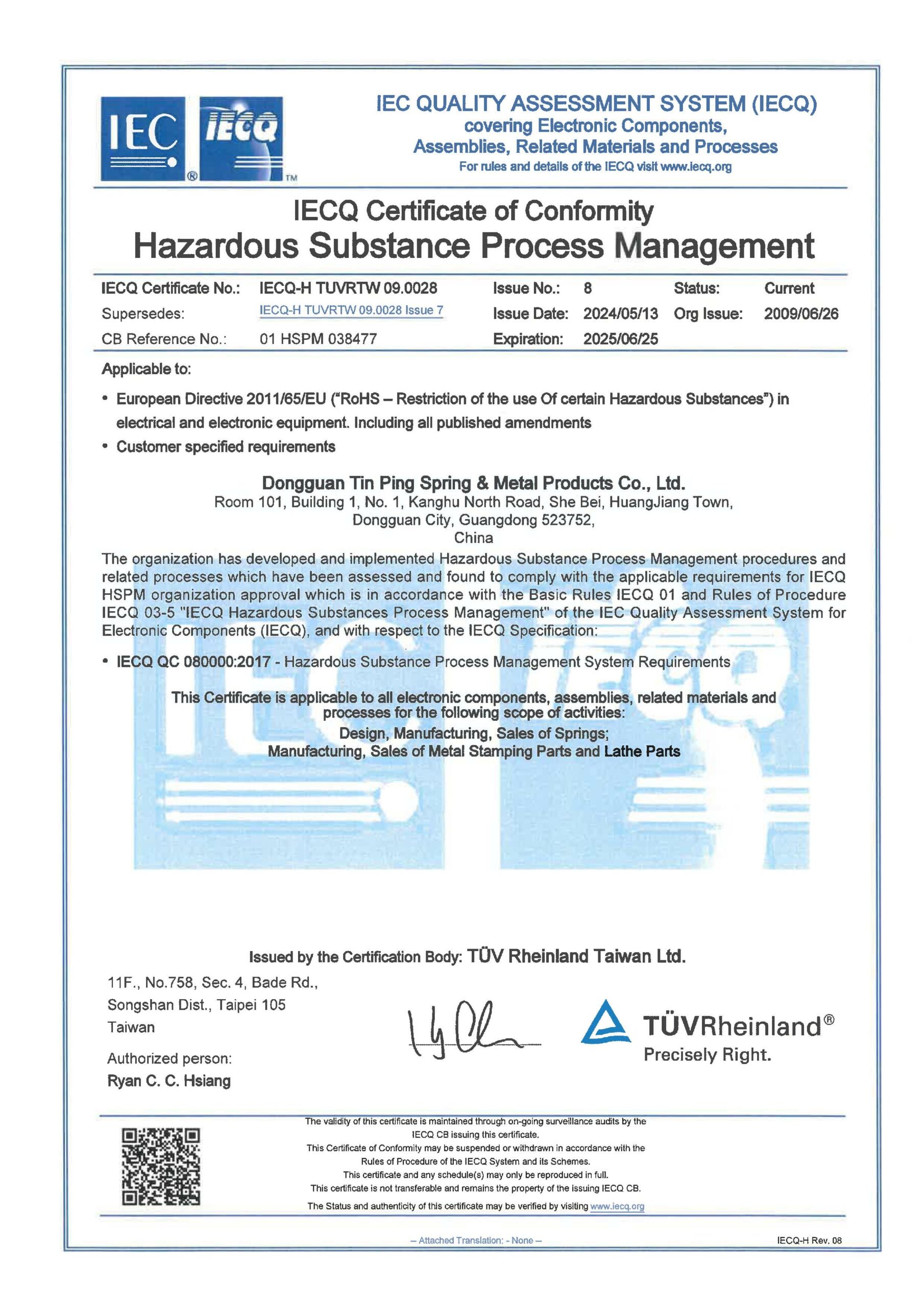

| HSPM | QC080000 |

Quality you can Trust

Quality Control Equipments

Tin Ping Metal Parts strive to keep up with the latest product analysis and quality control technologies to provide our clients with predictable and reliable products.

More

2.5D Vision Measuring System

- Working Area : 300 * 200 * 150 mm

- Measuring Distance : 90 mm

- Resolution : 0.001 mm

- XY Linear Accuracy : (2+L/100) µm

- Video Magnification : 20x - 180x

- Optical Magnification : 0.7x - 4.5x

More

Profilometer

- Measurement Resolution :

- 0.01 µm (800 µm range)

- 0.001 µm (80 µm range)

- 0.0001 µm (8 µm range)

- Measurement speed :

- 0.05, 0.1, 0.2, 0.5, 1.0 mm/s

- Measuring Condition Standards

- JIS1982 / JIS1994 / JIS2001 / ISO1997 / ANSI / VDA

More

Automatic Spring Tension / Compression Force Tester

- Testing the strength of Tension and compression spring

- Length and curvature test

- Provide statistics on measurements and tolerance

- Max Load : 10kgf(100N)

- Load Resolution : 0.1gf(0.001N)

- Max Range : 210mm

- Range Resolution : 0.001mm

Automatic Optical Inspection System

- 13 systems working around the clock.

- 3 of those can check for surface defects (e.g. Color difference, cracks, scratches and cleanliness)

- Dimension inspection :

- Diameter, Inside-Diameter, angle, thickness, length etc.

- Suitable for small metal parts and auto parts

- Daily capacity : 100k - 150k unit per system

More

Precision Automated Torsion Spring Tester

- Repetitive torson spring tester

- 3 load level (Angle)

- Fixed Repetition Test

- Back and Forth Test

- Max. Torque : 300Kgf-mm

- Max. Load : 50N

- Torque Sensitivity : 0.1gf-mm

- Load Sensitivity : 0.001N

More

Automatic Optical measurement machine

- Magnificate the measured object through a zoom lens, quickly scan, draw, construct and display it on screen

- Automatic multi-point measurement

- Accuracy : 0.002mm

- Max. Range (XYZ) : 300 x 200 x 200mm

- Max. Zoom : X200

- Measurement Item : Distance, concentricity, position, angle, diameter, curve, groove, etc.

More

Constant Force Spring Fatigue Tester

- Performs Tension Lift Test

- MAX. Test Distance : 710mm

- Vertical Speed Limit : 300mm/s

- Vertical Stop Interval : 0.1s MAX.

- Max. Simultaneous Tests : 5PCS

- Max. Cycles : 100000 / Test

- Live monitoring of test parameter and test cycles for each sample

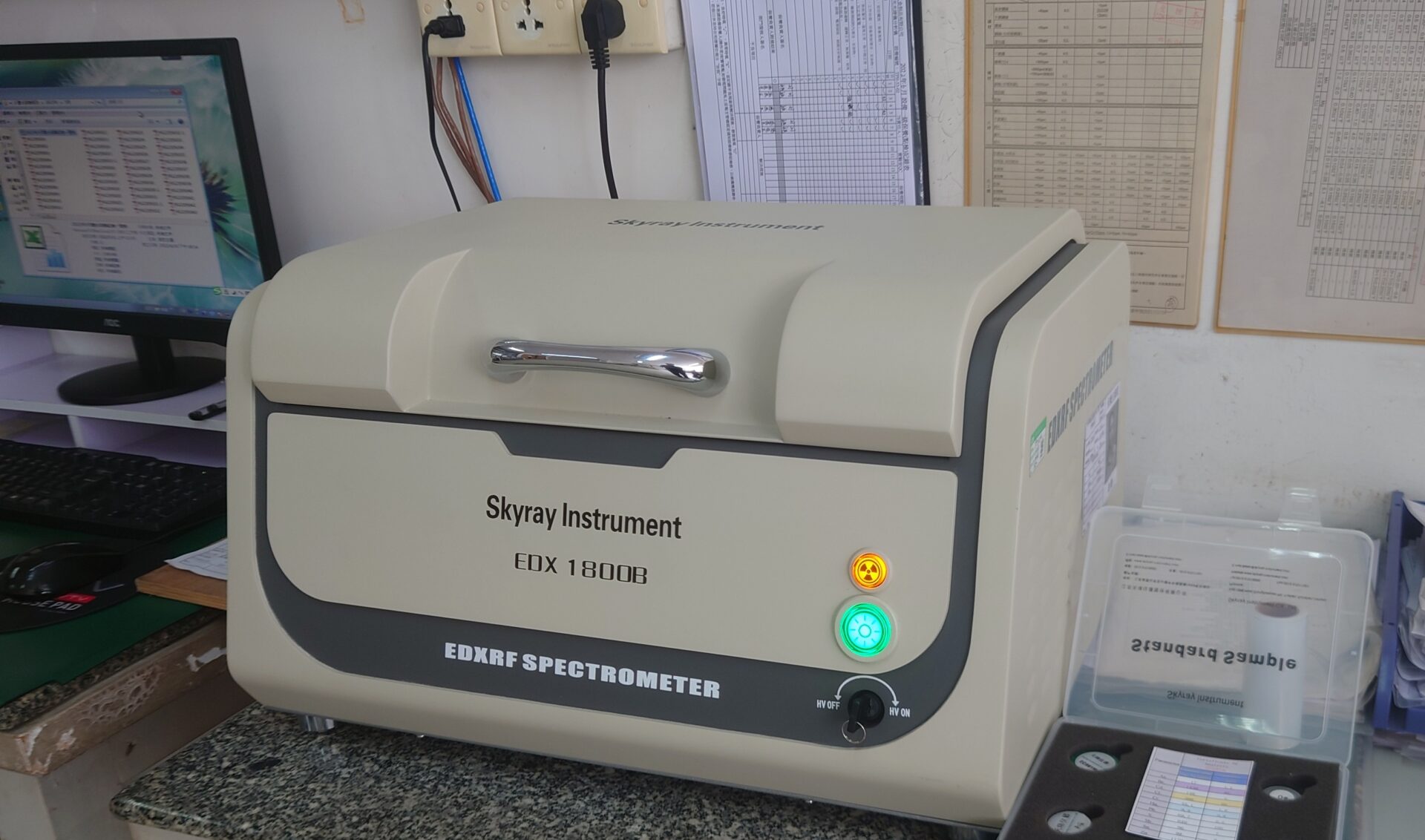

X-Ray Fluorescence Spectrometer

- Testing for hazardous substance in raw material and products

- ROHS 2.0

- Sensitivity : 2 ppm

- Repeatibility : 0.05%

- Daily Sampling is done by lab technicians to ensure results are valid

More

Salt Water Spray Chamber

- Testing Target

- Electroplated (Zinc, Nickel, Tin, Chromium) Products

- Stainless Steel

- Projects require saltwater spray testing

- NSS Neutral Salt Spray Testing Method

- ASTM B117, G8/T 10125

- Testing Standard

- GB/T6461 - 2002

" Methods For Corrosion Testing Of Metallic And Other Inorganic Coatings On Metallic Substrates--Rating Of Test Specimens And Manufactured Articles Subjected To Corrosion Tests "

- GB/T6461 - 2002

Need a Quote?

We are ready to take on any challenge, contact us for quote and get the parts exactly as you needed